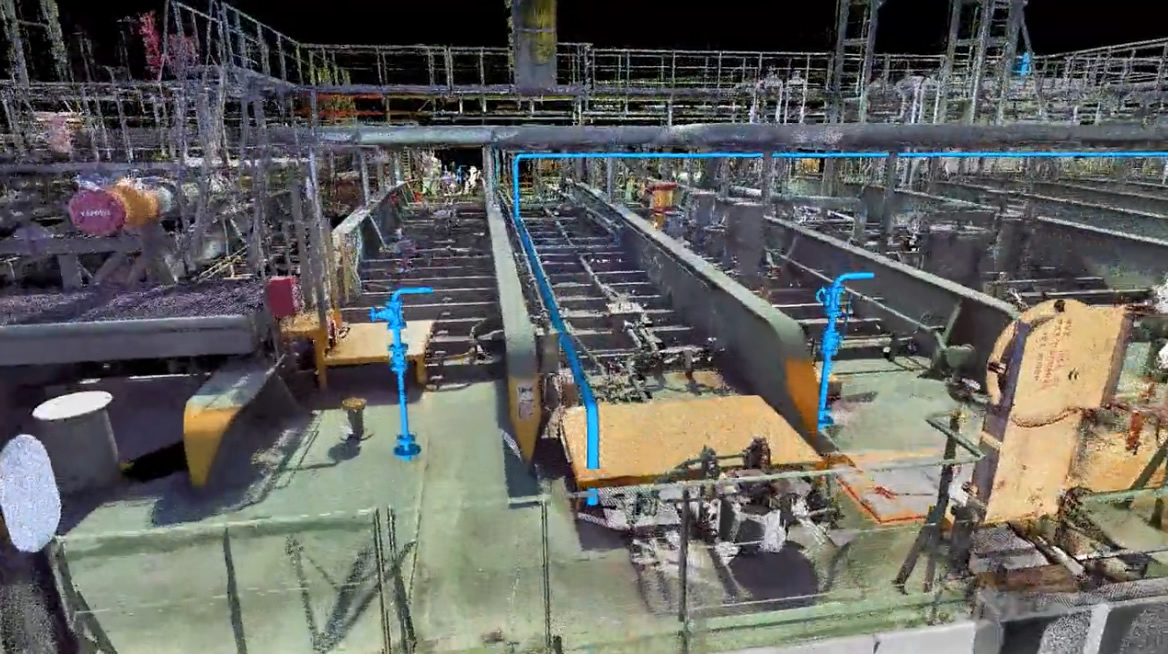

The image represents the vessel interface with the BWTS facility

Ballast Water Treatment Systems

Certification Service

The company is able to assist the shipowner in the IMO & USCG authorization phases of the BWTS plant, plan the activities for international concessions, assess the risks associated with the type of BWTS and verify / review the plant for certification purposes.

BSH is a federal authority, which works on behalf of the German administration, for obtaining the IMO Compliance of the BWTS.

Furthermore, as a Public Institution it manages maritime activities in areas of competence such as the prevention of dangers at sea, the publication of official nautical charts and surveying activities in the North Sea and in the Baltic Sea, as well as the forecasting of tides, waters and storm surges.

Audit and operational control for documentation validation of the BWTS plant in compliance with IMO.

BSH | Harmburg, Germany

Feasibility Studies

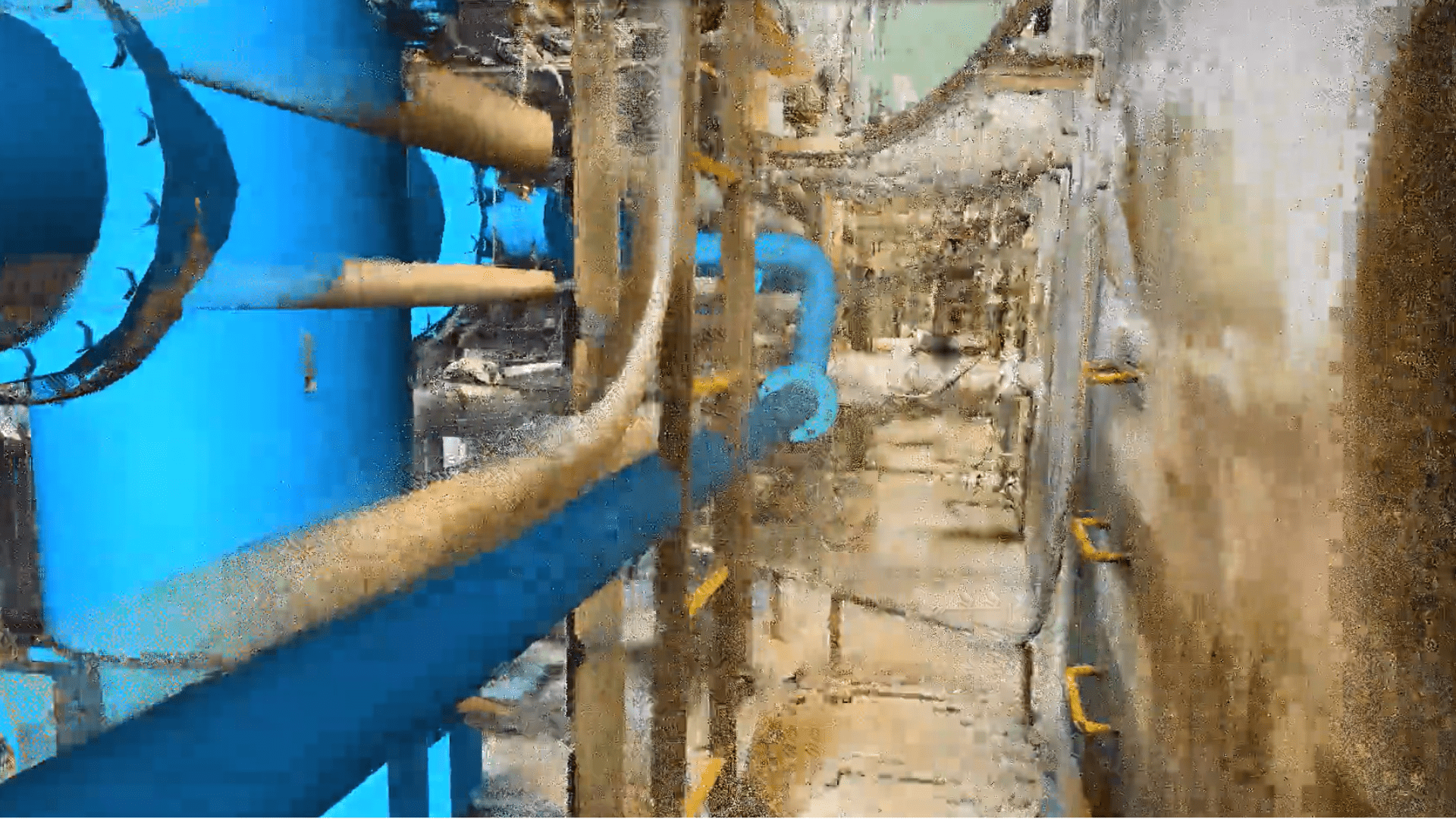

The real challenge is the verification of the spaces useful for connection with the BWTS in the context of existing ships that will have to be equipped with the BWTS. Verification of the starting point by on-board inspection and 3D laser scanning of the A.M. for connection with the BWTS rather than technical rooms potentially identified to accommodate a single BWTS box. 3D laser scanning allows a meaningful reduction of direct and indirect costs, especially in areas and spaces dense with components and systems.

The Laser 3D scanning operations of the first ship that will install an exclusive system – 100% Made in Italy – for the treatment of ballast water.

Reverse Engineering

Reverse engineering consists in the reconversion of the scans made on board the ship and their union using spherical alignment tools

3D Scan for Feasibility Study